2024 Doosan DVF 6500 5-Axis Machining Center. Under 1,000 cutting hours, equipped with Siemens Sinumerik One Control, 18K Spindle, 60-tool ATC, spindle oil chiller, and coolant chiller. Perfect for precise machining of complex parts

DN solutions DVF 6500 - New 2024 with under 1,000 Cutting Hours

Premium Simultaneous 5-axis Vertical Machining Center

The DVF series of premium 5 axis Vertical Machining Centers are built for high

precision machining of complex parts

Machine was DN Solutuons Loaner Demo Machine and can be Inspected Under Power.

Comes with a 6 Month parts warranty from DN Solutions.

CAPACITY

X axis travel 750 mm (29.52")

Y axis travel 785 mm (30.90")

Z axis travel 600 mm (23.62")

A axis travel +120 deg \ -120 deg

C axis travel 360 deg

Table Size 650mm dia. x 600mm (25.6" dia. x 23.6")

Max Work Piece Diameter 840 mm (33.07")

Max Work Piece Height 500 mm (19.685")

Max Table Load 1,000 kg (2,204 lbs)

SPINDLE:

Spindle nose to table top 110 mm to 710 mm (4.33" to 27.95")

Spindle speed 18,000 rpm

AC Spindle Motor (S6) 24 / 30 kW (32.2 / 40.2 hp)

Spindle Torque (S6) 155 nm (114.4 ft-lbs)

AUTOMATIC TOOL CHANGER:

Number of Tools 60

Tool Shank HSK63A

MACHINE DIMENSIONS:

Height 122", Floor Space Required 146" x 97"

Machine Weight 32,000 Lbs

Main Features

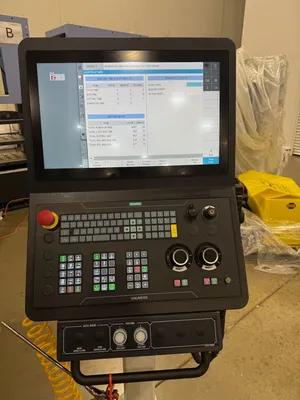

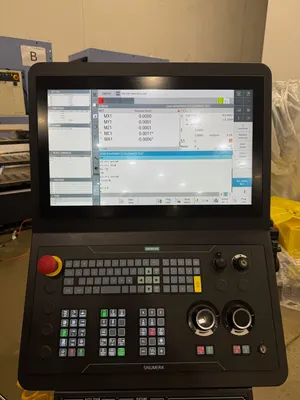

• Siemens Sinumerik One Control

• 5 Simultaneously controlled axes (X,Y,Z,A,C) with high precision, absolute rotary encoders

on A and C axes and absolute glass scales on XYZ axes

• Spindle oil chiller

• Coolant chiller

• Spindle orientation, load meter, override and rigid tapping

• Servo Driven, Double Arm ATC (60 tools)

• High rigidity, traveling column design with large linear roller guides

• Servo motors mounted directly to the oversized and pre-tensioned ball screws (X - 50 mm \

1.968", Y - 50 mm \ 1.968", Z - 40 mm \ 1.575")

• Ball screw shaft cooling for increased accuracy during long cycle times

• Fast rapid traverse rate (X - 45 m/min \ 1,771 ipm, Y - 45 m/min \ 1,771 ipm, Z - 45 m/min \

1,771 ipm)

• Z-axis thermal compensation by multiple temperature sensors and proprietary compensation

algorithms for increased precision

• 650mm dia. x 600mm (25.6" dia. x 23.6") T-Slot table surface

• 5 gigabyte program storage on CF card

• Renishaw probe ready - Probe not included (RMI-Q radio receiver, NC4 laser tool setter and software)

Other items included:

Chip Conveyor

Through Spindle Coolant

We use cookies to improve your experience. Privacy Policy.