Explore the power of precision with the Kitamura Mycenter HX1000i Horizontal Machining Center. 80" X, 52" Y, 54" Z, Equipped with a Fanuc 16i-MB CNC control, full 4th axis pallet contouring, high pressure coolant, and a massive 150-tool changer. Needs to Move, Make Offer!

X-AXIS TRAVEL.......................... 80.31"

Y-AXIS TRAVEL.......................... 51.97"

Z-AXIS TRAVEL.......................... 53.94"

B-AXIS INDEXING........................ FULL 4TH AXIS

TABLE WORK AREA (2 PALLETS)............ 39.37" X 39.37"

MAX WORKPIECE SIZE (DIA X H)........... 80.71" X 61.02"

TABLE LOAD CAPACITY.................... 6,600 LBS

DISTANCE FROM TABLE SURFACE TO SPINDLE CENTER.. 1.97" TO 53.94"

DISTANCE FROM TABLE CENTER TO SPINDLE NOSE..... 5.91" TO 59.84"

SPINDLE SPEED (4-STEP GEARED).......... 20 TO 8,000 RPM

SPINDLE MOTOR.......................... 40 HP

MAXIMUM TORQUE......................... 897.7 FT/LBS

RAPID FEED RATE (X,Y,Z)................ 1,417 IPM

CUTTING FEE RATE....................... 0 TO 1,417 IPM

SPINDLE TAPER................. BT-50 DUAL CONTACT (CAN BE CHANGED TO CAT)

TOOL CHANGER CAPACITY.................. 150 TOOLS

REQUIRED MACHINE FLOOR SPACE: 202.6" X 386.8" X 149.5" HIGH

APPROXIMATE MACHINE WEIGHT: 120,000 LBS

POWER REQUIREMENT: 80 KVA, 220 V AC, 3 PHASE

EQUIPPED WITH:

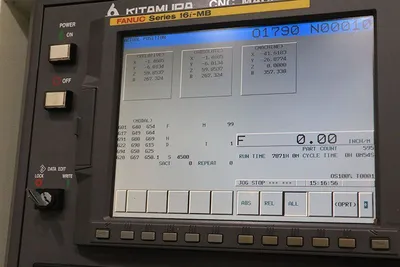

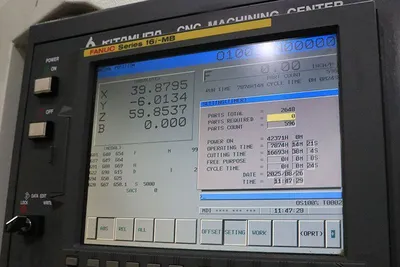

- FANUC 16i-MB CNC CONTROL

- FULL 4TH AXIS PALLET CONTOURING

- HIGH PRESSURE COOLANT THROUGH THE SPINDLE, 1,000 PSI

- HEAVY DUTY BOX WAY CONSTRUCTION

- RENISHAW PROBING SYSTEM

- MISC BT-50 TOOL HOLDERS

- HIGH PRECISION TWIN BALL SCREWS AND TWIN SERVO MOTORS

- LINEAR SCALE FEEDBACK ON ALL AXES

- CHIP CONVEYOR

** MACHINE CUT PRIMARILY ALUMINUM & STAINLESS

** AVAILABLE FOR IMMEDIATE INSPECTION & PURCHASE

** AVAILABLE WITH A TSUDAKOMA RBA-500R ROTARY TABLE

WE WILL PREP AND LOAD FOR YOU

Inspect under power in our warehouse

NEEDS TO SELL TO MAKE ROOM - CALL TO MAKE A DEAL

We use cookies to improve your experience. Privacy Policy.